Expert Guide: Can You Solder Speaker Wire & Enhance Audio?

Can you solder speaker wire? The answer is a resounding yes! If you’ve ever faced the frustration of a loose connection or a faulty speaker wire, soldering can be a simple yet effective solution that ensures a reliable and uninterrupted audio experience. By joining the wire and the connector through a strong and secure bond, soldering eliminates the risk of loose connections that result in crackling, static, or even complete loss of sound. In this article, we’ll guide you through the step-by-step process of soldering speaker wire, equipping you with the knowledge and skills to tackle this DIY task with confidence. So, let’s dive in and explore the world of soldering speaker wire together!

Can You Solder Speaker Wire?

Soldering speaker wire can be a useful skill to have if you’re an audio enthusiast or someone who deals with electronics. It allows you to create secure and reliable connections between your speaker cables, preventing signal loss and ensuring high-quality sound reproduction. In this article, we’ll explore the process of soldering speaker wire, discuss its benefits, and provide step-by-step instructions to help you successfully complete the task.

Understanding Speaker Wire

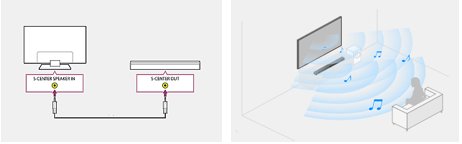

Before diving into the details of soldering speaker wire, it’s important to have a basic understanding of what speaker wire is and how it works. Speaker wire is a type of electrical cable specifically designed for connecting audio devices, such as amplifiers and speakers. It consists of two conductors, usually copper, that carry the audio signal from the amplifier to the speaker.

The quality of the speaker wire can greatly impact the overall sound quality of your audio system. High-quality speaker wire minimizes resistance and interference, allowing the audio signal to travel more efficiently and accurately. This is why it’s crucial to choose the right gauge and type of wire for your specific needs.

The Benefits of Soldering Speaker Wire

Soldering speaker wire offers several benefits that can enhance the performance and reliability of your audio system. Here are some key advantages:

- Secure connections: Soldering creates a strong and permanent connection between the wire and the connector, reducing the chances of accidental disconnections or signal interruptions.

- Improved signal transfer: Soldering eliminates the possibility of loose or frayed wire ends, ensuring a consistent and uninterrupted flow of the audio signal.

- Prevents oxidation: By soldering the wire ends, you protect them from oxidation, which can deteriorate the metal over time and result in poor conductivity.

- Aesthetically pleasing: Soldering provides a neat and professional appearance to your speaker connections, making your audio system look more organized and visually appealing.

Tools and Materials You’ll Need

Before you begin soldering speaker wire, gather the necessary tools and materials. Here’s a list of what you’ll typically need:

- Soldering iron

- Soldering station or stand

- Solder (lead-free is recommended)

- Wire strippers

- Heat shrink tubing or electrical tape

- Flux (optional)

- Desoldering pump or solder wick (in case you need to remove existing solder)

Step-by-Step Guide to Soldering Speaker Wire

Now, let’s walk through the process of soldering speaker wire. Follow these steps to achieve a secure and reliable connection:

- Prepare the wire: Start by stripping off about half an inch of insulation from the ends of the speaker wire. Use wire strippers to ensure clean and precise cuts.

- Tin the wire ends: Apply a small amount of solder to the exposed copper wire ends. This process, known as tinning, helps improve the soldering process by promoting better heat transfer and reducing the chance of cold solder joints.

- Prepare the connector: If you’re using connectors with your speaker wire, make sure they are clean and free from any solder residue or debris. If necessary, use desoldering tools to remove any existing solder from the connectors.

- Heat the wire and connector: Using a soldering iron, heat the wire and connector simultaneously. The heat will melt the solder and create a strong bond between the wire and the connector.

- Apply solder: Touch the soldering iron tip to the joint where the wire and connector meet. Allow the solder to flow into the joint and create a solid connection. Be careful not to use excessive solder, as it can result in messy and unreliable connections.

- Inspect and protect: Once the solder has cooled down, inspect the joint to ensure it’s solid and free from any cold solder joints or excess solder. If desired, cover the soldered joint with heat shrink tubing or electrical tape for added protection and insulation.

Tips for Successful Soldering

Here are some additional tips to help you achieve successful soldering results:

- Ensure a clean workspace, free from any flammable materials or clutter.

- Use a soldering iron with an appropriate wattage for the job. Higher wattage irons are suitable for larger wires, while lower wattage irons work better for smaller wires.

- Avoid applying excessive heat to the wire and connectors, as it can damage the insulation or components.

- If using flux, apply a small amount to the wire and connector before soldering. Flux helps improve solder flow and bond quality.

- Practice good soldering technique by applying solder to the joint, not the soldering iron tip. The solder should melt and flow into the joint naturally.

- Allow the soldered joint to cool down completely before handling it or connecting it to your audio system.

With these tips in mind and by following the step-by-step guide, you’ll be able to solder speaker wire confidently and achieve reliable connections for your audio system.

Frequently Asked Questions

Can you solder speaker wire?

Yes, you can solder speaker wire to ensure a secure and reliable connection. Soldering is the process of joining two pieces of metal by melting a filler metal (solder) between them, creating a strong bond. Soldering speaker wires can be particularly useful when connecting them to speaker terminals, connectors, or other audio equipment.

What tools do you need to solder speaker wire?

To solder speaker wire, you will need a few basic tools, including a soldering iron, solder wire, wire cutters/strippers, and heat shrink tubing (optional). The soldering iron is used to heat the solder, while the wire cutters and strippers are essential for preparing the wire ends. Heat shrink tubing can provide additional protection and insulation for the soldered joint.

How do you solder speaker wire?

The process of soldering speaker wire involves a few simple steps. First, strip about 3/4 inch of insulation from the end of the wire using wire strippers. Then, twist the wire strands together to prevent fraying. Heat the soldering iron and apply it to the twisted wire strands. Once the wire is heated, touch the solder wire to the joint. Allow the solder to melt and flow evenly around the wire strands. Finally, let the joint cool down and inspect it for a clean and secure connection.

Why should you solder speaker wire?

Soldering speaker wire provides several benefits. It creates a strong electrical connection, ensuring excellent signal transfer between the speaker and the audio equipment. Soldering also prevents fraying and loosening of the wire strands, reducing the risk of poor audio quality or intermittent connections. Additionally, soldering can enhance the overall durability and longevity of the speaker wire connection.

Can you use other methods to connect speaker wire besides soldering?

Yes, besides soldering, there are alternative methods to connect speaker wire. These include using crimp connectors, screw terminals, or banana plugs. Crimp connectors use a specialized tool to compress the connector onto the wire, creating a secure connection. Screw terminals involve tightening the wire around a screw with a screwdriver. Banana plugs are commonly used with binding posts and provide a convenient and removable connection. While these methods are viable alternatives, soldering is often preferred for its reliability and long-term performance.

Final Thoughts

In conclusion, soldering speaker wire is a viable option for ensuring a secure and reliable connection. By using a soldering iron and appropriate tools, you can effectively join the wire ends together, enhancing the audio quality and minimizing the risk of loose connections. Soldering also allows for better signal transmission and reduces the chances of interference. So, if you’re wondering, “Can you solder speaker wire?” the answer is yes. Soldering provides a professional and long-lasting solution for optimizing your speaker system’s performance.